KyuluxのHyperfluorescence™がAMOLEDに採用

Two weeks ago we announced a collaboration with WiseChip Semiconductor to use Hyperfluorescence emitters in WiseChip’s PMOLED displays. In early July, Wisechip demonstrated a working yellow monochrome prototype – with commercial production expected by the end of 2017 for both yellow and green displays.

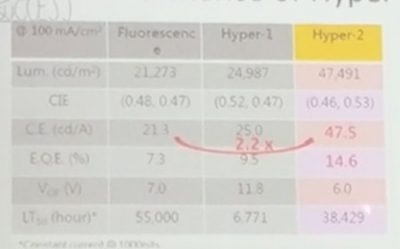

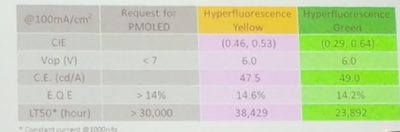

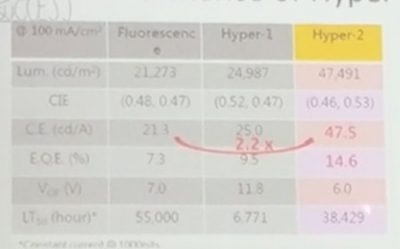

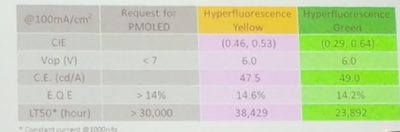

Hyperfluorescence emitters enabled WiseChip to boost the efficiency by around 50% while still maintaining the color purity and a lifetime of over 30,000 hours (LT50).

Hyperfluorescence emitters enabled WiseChip to boost the efficiency by around 50% while still maintaining the color purity and a lifetime of over 30,000 hours (LT50).

Following this announcement, questions were raised as to the relevance of this technology for use in AMOLED displays, which represents a much larger market ($20 billion in 2017 and continue to grow fast compared to PMOLEDs’ $0.5 – 1 billion). Even though one should not rush to discount the PMOLEDs market, which is expected to stay relevant and grow (with the rise of wearables and introduction of flexible and transparent displays), it is clear that the AMOLED segment of the market remains dominant. In this article, we set out to clarify the difference between the two technologies and lift any doubt regarding the readiness of HF technology for AMOLED displays.

Following this announcement, questions were raised as to the relevance of this technology for use in AMOLED displays, which represents a much larger market ($20 billion in 2017 and continue to grow fast compared to PMOLEDs’ $0.5 – 1 billion). Even though one should not rush to discount the PMOLEDs market, which is expected to stay relevant and grow (with the rise of wearables and introduction of flexible and transparent displays), it is clear that the AMOLED segment of the market remains dominant. In this article, we set out to clarify the difference between the two technologies and lift any doubt regarding the readiness of HF technology for AMOLED displays.

From the device maker’s point of view, a PMOLED display is a simple display that is limited in resolution compared to an AMOLED but is easier to produce and is cheaper. While PMOLEDs are used in applications such as fitness bands and secondary displays, AMOLED displays are found in higher-end devices like smartphones, laptops and TVs.

From the device maker’s point of view, a PMOLED display is a simple display that is limited in resolution compared to an AMOLED but is easier to produce and is cheaper. While PMOLEDs are used in applications such as fitness bands and secondary displays, AMOLED displays are found in higher-end devices like smartphones, laptops and TVs.

The brightness of an OLED pixel is determined by the applied voltage. A PMOLED design requires very high voltages, much higher than AMOLEDs, but these high voltages cause the materials to degrade more quickly. This means that PMOLED driving is even more challenging than AMOLED driving. When Wisechip tested our materials, they did so at a constant current generating 1,000 nits – which is very bright (the maximum brightness of most mobile phones does not even reach 500 nits). Kyulux’s materials have already achieved PMOLED readiness, and so we feel AMOLED applications should not be far behind.

The brightness of an OLED pixel is determined by the applied voltage. A PMOLED design requires very high voltages, much higher than AMOLEDs, but these high voltages cause the materials to degrade more quickly. This means that PMOLED driving is even more challenging than AMOLED driving. When Wisechip tested our materials, they did so at a constant current generating 1,000 nits – which is very bright (the maximum brightness of most mobile phones does not even reach 500 nits). Kyulux’s materials have already achieved PMOLED readiness, and so we feel AMOLED applications should not be far behind.

As can be seen in Wisechip’s results above, our yellow material is ready for commercialization. The performance of our materials for AMOLED displays with their lower voltages will be even better – internal testing have shown our EQE to reach 18-20% with lower voltages. The green results are still preliminary as this was the 2nd stage of the development project, and we are certain we will meet Wisechip’s lifetime goals in a few months.

As can be seen in Wisechip’s results above, our yellow material is ready for commercialization. The performance of our materials for AMOLED displays with their lower voltages will be even better – internal testing have shown our EQE to reach 18-20% with lower voltages. The green results are still preliminary as this was the 2nd stage of the development project, and we are certain we will meet Wisechip’s lifetime goals in a few months.

As we keep developing our materials and improving the whole stack, Hyperfluorescence will truly shine!

As we keep developing our materials and improving the whole stack, Hyperfluorescence will truly shine!

Hyperfluorescence emitters enabled WiseChip to boost the efficiency by around 50% while still maintaining the color purity and a lifetime of over 30,000 hours (LT50).

Hyperfluorescence emitters enabled WiseChip to boost the efficiency by around 50% while still maintaining the color purity and a lifetime of over 30,000 hours (LT50).

Following this announcement, questions were raised as to the relevance of this technology for use in AMOLED displays, which represents a much larger market ($20 billion in 2017 and continue to grow fast compared to PMOLEDs’ $0.5 – 1 billion). Even though one should not rush to discount the PMOLEDs market, which is expected to stay relevant and grow (with the rise of wearables and introduction of flexible and transparent displays), it is clear that the AMOLED segment of the market remains dominant. In this article, we set out to clarify the difference between the two technologies and lift any doubt regarding the readiness of HF technology for AMOLED displays.

Following this announcement, questions were raised as to the relevance of this technology for use in AMOLED displays, which represents a much larger market ($20 billion in 2017 and continue to grow fast compared to PMOLEDs’ $0.5 – 1 billion). Even though one should not rush to discount the PMOLEDs market, which is expected to stay relevant and grow (with the rise of wearables and introduction of flexible and transparent displays), it is clear that the AMOLED segment of the market remains dominant. In this article, we set out to clarify the difference between the two technologies and lift any doubt regarding the readiness of HF technology for AMOLED displays.

AMOLED vs PMOLED

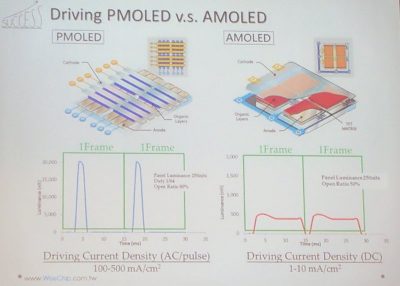

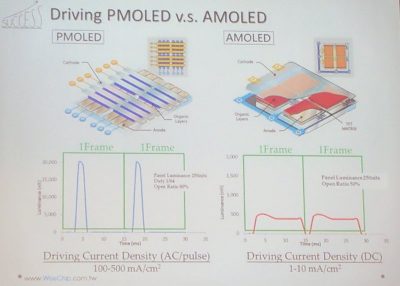

The main difference between the two OLED types is the driving (control) mechanism. PMOLED stands for Passive-Matrix OLED, and these displays employ a relatively simple control scheme in which each row (or line) is controlled sequentially (one at a time). PMOLED panels do not contain a storage capacitor and so the pixels in each line are actually off most of the time – they are only lit each line at a time. An AMOLED display is also controlled one line at a time – but the display uses an Active-Matrix driver – which includes capacitors that retain the pixel information until the next line refresh. This means two things: PMOLED devices are limited in resolution and are thus suited for simple applications and the display is driven in short pulses of high brightness (voltages) which harms the stability (lifetime) of the emitting materials. From the device maker’s point of view, a PMOLED display is a simple display that is limited in resolution compared to an AMOLED but is easier to produce and is cheaper. While PMOLEDs are used in applications such as fitness bands and secondary displays, AMOLED displays are found in higher-end devices like smartphones, laptops and TVs.

From the device maker’s point of view, a PMOLED display is a simple display that is limited in resolution compared to an AMOLED but is easier to produce and is cheaper. While PMOLEDs are used in applications such as fitness bands and secondary displays, AMOLED displays are found in higher-end devices like smartphones, laptops and TVs.

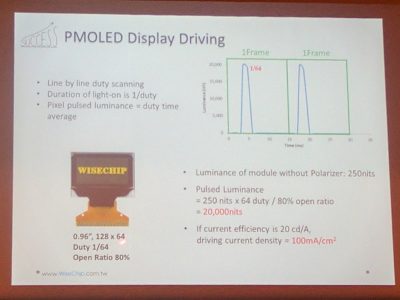

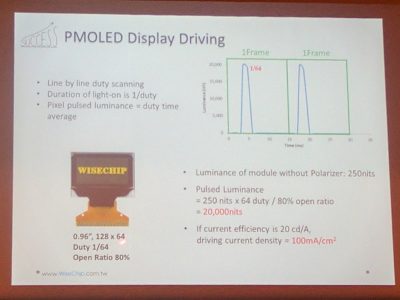

PMOLED driving – high brightness pulses

Each line in a PMOLED display is only lit for a very short time. Take a 100×10 PMOLED for example – there are 10 lines and each will be lit for only a 1/10 of a second. To maintain a certain brightness, each pixel actually has to be 10X as bright. The higher the resolution, the brighter you need to drive these pixels. The brightness of an OLED pixel is determined by the applied voltage. A PMOLED design requires very high voltages, much higher than AMOLEDs, but these high voltages cause the materials to degrade more quickly. This means that PMOLED driving is even more challenging than AMOLED driving. When Wisechip tested our materials, they did so at a constant current generating 1,000 nits – which is very bright (the maximum brightness of most mobile phones does not even reach 500 nits). Kyulux’s materials have already achieved PMOLED readiness, and so we feel AMOLED applications should not be far behind.

The brightness of an OLED pixel is determined by the applied voltage. A PMOLED design requires very high voltages, much higher than AMOLEDs, but these high voltages cause the materials to degrade more quickly. This means that PMOLED driving is even more challenging than AMOLED driving. When Wisechip tested our materials, they did so at a constant current generating 1,000 nits – which is very bright (the maximum brightness of most mobile phones does not even reach 500 nits). Kyulux’s materials have already achieved PMOLED readiness, and so we feel AMOLED applications should not be far behind.

As can be seen in Wisechip’s results above, our yellow material is ready for commercialization. The performance of our materials for AMOLED displays with their lower voltages will be even better – internal testing have shown our EQE to reach 18-20% with lower voltages. The green results are still preliminary as this was the 2nd stage of the development project, and we are certain we will meet Wisechip’s lifetime goals in a few months.

As can be seen in Wisechip’s results above, our yellow material is ready for commercialization. The performance of our materials for AMOLED displays with their lower voltages will be even better – internal testing have shown our EQE to reach 18-20% with lower voltages. The green results are still preliminary as this was the 2nd stage of the development project, and we are certain we will meet Wisechip’s lifetime goals in a few months.

As we keep developing our materials and improving the whole stack, Hyperfluorescence will truly shine!

As we keep developing our materials and improving the whole stack, Hyperfluorescence will truly shine!